| 最大装料量 | 150kg |

|---|---|

| 吊钩回转直径 | 300mm |

| 吊具高度 | 900mm |

| 抛头数量 | 2 |

| 总丸料量 | 175kg/min |

| 产地 | 江阴 |

| 额定电压 | 220V |

| 功率 | 3.75kw |

| 规格 | 面议 |

| 类型 | 吊钩式 |

| 新旧程度 | 全新 |

| 作用对象 | 钢材抛丸清理机 |

| 品牌 | 碧砂 |

| 型号 | RH2-3/9 |

| 加工定制 | 是 |

| 除尘风量 | 1400m3/h |

| 适用星级 | 所有星级 |

| 是否原厂 | 是 |

本公司供应抛丸机碧砂RH2-3/9碧砂 RH2-3/9 吊钩式 钢材抛丸清理机 3.75kw 江阴,质量保证,欢迎咨询洽谈。

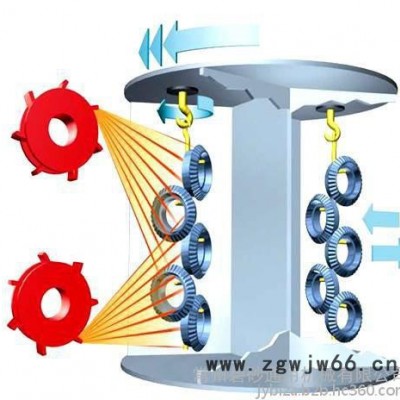

RH型旋转吊钩抛丸清理机Rotary Hook Shot Blasting Machine

RH型旋转吊钩抛丸清理机适用于工件的表面清理,如铝铸件的去毛刺,锻件除锈,铸件除砂,尤其适用于由于形状和尺寸的限制不宜翻转的工件。有几种规格可选,每钩**大装载能力可达600kg。设备自动化程度高,可整合到整个生产线上,装卸料可无需人工操作,可用机械手代替操作。

Rotary hook shot blasting machine for cleaning the surface of the workpiece,Such as aluminum castings forgings castings deburring, rust, sand removal, especially suitable for the shape and size restrictions not turning workpiece. There are several specifications of selectable, each hook maximum loading capacity of up to 600kg. A high degree of automation equipment, can be integrated into the production line, material handling can be obtained without the need for manual operation, can be used instead of operating manipulator.

设计和操作顺序the sequence of design and operation

设备无需地基,室体主要由旋转的抛丸室组成,抛丸室又分隔为两部分,抛丸单元和丸料清除单元。每个分隔单元装有旋转吊钩,吊钩上悬挂被清理的工件。设备装料的区域是敞开的,这样,当工件在一侧室体被抛丸清理时,可以在另一侧室体卸料和装料。无论室体旋转到下一任何位置时,只要室体停止旋转,丸料流立即被切断。连续旋转的吊钩,可以在抛头前针对每个抛丸周期,标识3个不同的位置,以避免抛丸死角。丸料经过分离单元去除杂质重新喂到抛丸器里。

Device without foundation, the cabin is mainly composed of a rotary blast cabin, a blast cabin is divided into two parts, shot blasting unit and abrasive removal unit. Each separating unit is provided with a rotary hook, hook hanging cleaning workpiece. Equipment loading area is open, so that, when the workpiece in a side cabin is shot blast cleaning, can be in another compartment body loading and unloading. Both the cabin rotates to the next to any position, as long as the cabin stops rotating, abrasive flow is cut off. Continuous rotary hook in front, can throw for each shot cycle, identifies 3 different positions, in order to avoid shot dead. abrasive after separation unit to remove impurities to feed to the shot blasting machine.

结构设计特点Structure design characteristics

设备室体用高耐磨性能材料作为衬板。独特的密封设计,确保了在抛丸过程中丸料不会泄露。安装在设备装料/卸料口边上的2个安全开关能够确保工件卡死的情况下完全切断设备的运行。设备后侧的门为室体和抛丸器的维护和检修提供了方便。

Cabin with high wear resistance material as the liner. Unique sealing design, to ensure that abrasive will not escape during blast cleaning. The 2 safety switches equipped on the side of loading / unloading position can ensure completely to cut off equipment operation in clamping case . Rear door is convenient for cabin and blast wheels maintenance and repair.

技术参数technical data

项目item | 产品型号products specification | ||

RH2-3/9 | RH2-5.5/12 | RH2-8.5/15 | |

**大装料量Max. loading(kg) | 150 | 300 | 600 |

吊钩回转直径the rotary diameter of cluster(mm) | 300 | 550 | 850 |

The hight of cluster吊具高度(mm) | 900 | 1200 | 1500 |

抛头数量blast wheels number | 2 | 2 | 2 |

抛头功率blast wheel power(kw) | 3.75 | 5.5/7.5 | 7.5/11 |

总丸料量total abrasive throughput (kg/min) | 175 | 210/240 | 240/360 |

除尘风量dust collector air volume(m3/h) | 1400 | 3400 | 5100 |