| 中心高 | 97.5 |

|---|---|

| 中心套孔直径 | 80(mm) |

| 工作台面直径 | 160.2(mm) |

| 主轴连接尺寸 | 40(mm) |

| T型槽宽度 | 14(mm) |

| 定位键宽度 | 14(mm) |

| 分度精度 | +-1.0(s) |

| 重复精度 | +-0.3(s) |

| 是否库存 | 否 |

| 是否批发 | 是 |

| 材质 | 高碳钢 |

| 产地 | 德国 |

| 执行标准 | 德标 |

| 适用机床 | 皆可 |

| 品牌 | 霍夫曼 |

| 型号 | CNC160.2/TMI55 |

| 质量认证 | CCC |

1、TMI-FL扭矩电机法兰式(内置扭矩电机)

特点描述:

TMI??FL 型号的法兰安装形式从设计上为分度头安装到机床上提供了便利。相对于传统的TMI 系列,这种型号唯一的不同就是法兰安装方式和圆形防护。分度头内部的所有元件和转台的技术指标都与标准的TMI 系列完全相同。

其外壳是由高规格的钢材或者高强度铝合金制成,具有非常紧凑的设计,并且具有很好的刚性。防护有很高的密封等级能防止切削液和加工屑侵入。通过圆形的定位卡口和沉孔可以很容易的安装到机床上,电缆插座和其它连接(例如冷却、液压等)排列在转台尾部,避免侧面安装可能的机械干涉,这样保证了转台能够垂直或者轴向推入安装孔。多个单元也能挨个放置用于多头加工。

这种紧凑的设计也具有很高的通用性,各种接口一致,在转台服务和维修时有很好的互换性,这保证了转台带来最大的生产效益。

2、技术参数:

| |

CNC 160.2/TMI55-SO with Direct-Drive |

|

|

|

|

|

Description 产品描述 |

|

HOWIMAT CNC 160.2/TMI55-SO 型号 |

|

|

|

|

|

Indexing precision deviation (depends on the direct-measuring system) |

|

分度精度偏差(取决于直接编码器) |

|

Radial and axial run-out端跳 | max.+/-0.003mm |

Spindle face diameter台面直径 | (h6) 160mm |

Spindle-bore中心孔 | 80H6(125mm deep) |

Length of device (without additional accessories)总长度(不含额外的配件) | 235mm |

Center height without a base-plate无底座中心高度 | 97,5mm |

Case-dimensions包装尺寸 | 195x195mm |

Table speed转速 | max.600rpm |

(depends on operation and additional accessories)(取决于控制和附加设备) | 110x150mm |

Axial-Radial-bearing-diameter轴承直径 |

|

Continuous torque (water cooled)连续扭矩(水冷) | 48Nm |

Peak torque (Saturation range)(1s) 峰值扭矩(饱和范围)(1秒) | 74Nm |

max. tangential torque(clamped) 最大切向力矩(夹紧) | ca. 500Nm (max. 50bar) |

max. load for movement(depends on operation) 最大负载(取决于控制) | ca. 100kg(centrical) |

max. tilting torque 最大倾覆扭矩 | 800Nm |

max. load for axial bearing 轴向最大载荷 | 35000N |

(pneumatic clamp with “emergency stop” function; optionally available) |

|

(“气动紧急停止”功能夹紧;可选配) |

|

|

|

Housing is made from ductile cast iron and precision-grinded外壳是经过精密磨削的球墨铸铁制成 | |

Unit completely sealed and prepared for overpressure with 0,4bar转台完全密封,可超压0,4bar | |

Incl. hollow-shaft motor; DC-link voltage 600V 包含空心轴电机;直流电压600V | |

--with sensor for temperature UP62; KTY84-130; PTC110包括温度传感器UP62 ; KTY84- 130 ; PTC110 | |

--Continuous current (cooled) 9A; peak current (cooled)15A 连续电流(冷却)9A ;峰值电流(冷却)15A | |

Incl. plugs for Power, Encoder and Temp.-Sensor connection包含电源插头,编码器和温度传感器 | |

-- 6-pin squared turnable plug for power-connection 6针方形可旋转电源插头 | |

-- 17-pin squared turnable plug for signal-connection17针方形可旋转信号连接插头 | |

-- Optional: 7-pin squared plug for separate PTC and KTY sensors可选:7针插头,用于PTC传感器 | |

-- other pin-arrangements on request可根据要求提供其它插头 |

|

和KTY传感器连接 |

|

incl. spindle-clamp inside包含内部液压夹紧 |

|

-- clamping power ca. 500Nm with 50bar (pressure max. 50bar)夹紧力约500Nm,50bar(压力最大50bar) | |

--without controller, unit or transformer for pressure, without tubes不含控制器,液压单元,变压器和连接线 | |

Incl. prepared for connection a water-cooling-system含水冷却系统接头 |

|

--without cooling-unit, controller and without tubes.不带水冷单元,控制器和连接线 | |

incl. special preparation for mounting aRCN 8580 measuring system含特殊RCN8580编码器系统 | |

--incl.special mounting preparation with special flange for fitting the additional special housing | |

of the encoder; completely sealed + prepared for overpressure. |

|

含特殊编码器外壳的法兰接口;完全密封+超压处理 |

|

--Center-bore through spindle ca. 80mm by usingRCN8580 |

|

使用编码器RCN8580,中心孔过宽为80mm |

|

-- incl. Installation of the encoder含编码器安装 |

|

|

|

|

|

|

|

Direct measuring-system HeidenhainRCN8580 (absolute-encoder) |

|

直接编码器海德汉RCN8580(绝对值编码器) |

|

--absolute-encoder, withEnDat2.2Serial Interface绝对编码器, EnDat2.2串行接口 | |

-- indexing accuracy +/-1,0 angular seconds分度精度+ / -1,0角秒 |

|

-- 32768 lines/ per turn and with a bore diameter of 60mm 32768线/转,带有60mm的孔径 | |

-- 29bit,536870912 Positions/ per turn 29位,536870912位置/转 |

|

-- Incl. ca. 1mtr. Cable(open cable end)包含约1m长电缆(开放电缆端) | |

-- Without preparation and mounting不包准备和安装 |

|

|

|

|

|

Supplied by customer:客户端需要准备 |

|

base-plate for mounting the rotary on the machine转台床身安装底座 |

|

Cable-set and cabling incl. all needed plugs and additional covers to protect the area with the electic connectors and plugs外置电缆,接头和 防护罩 |

|

All needed parts and units incl. the controlling for pneumatic,hydraulic and the water | |

-cooling-system外置所需气动, 液压和水冷控制器 |

|

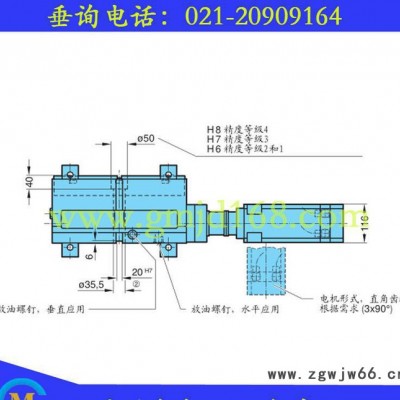

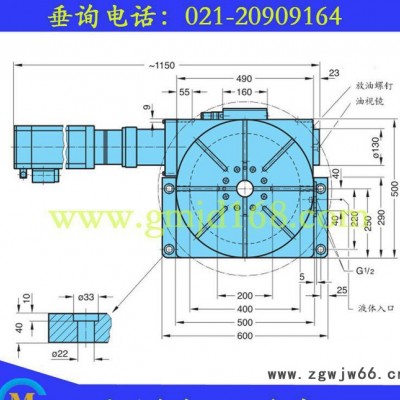

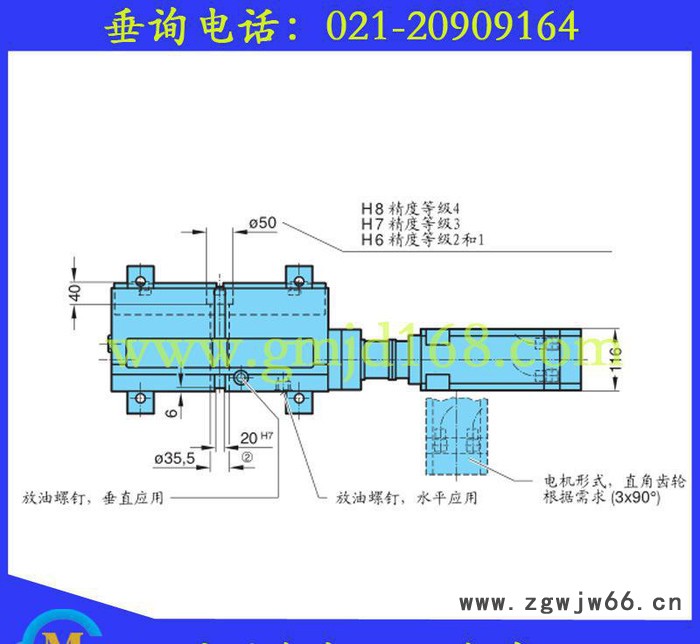

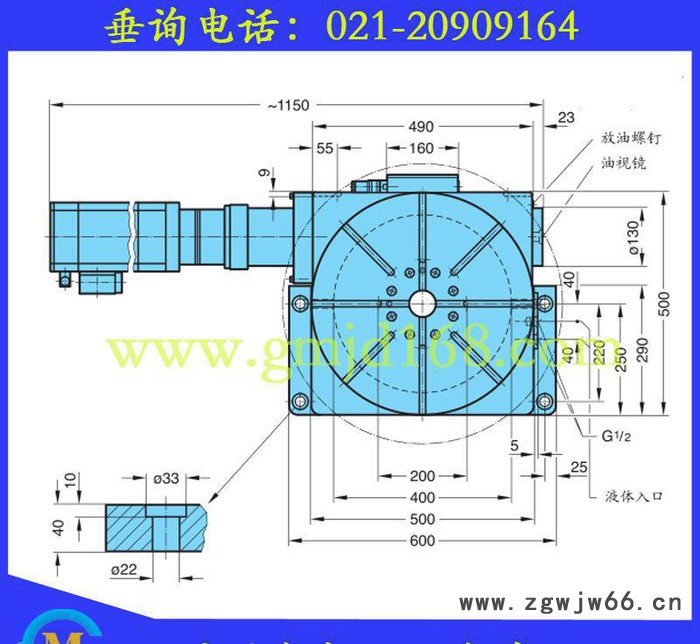

3、图纸